Facilities – MP 2

Facilities – MP 2

@ Maryland Packaging

@ Maryland Packaging

3610 Commerce Drive

Halethorpe, MD 21227

3610 Commerce Drive

Halethorpe, MD 21227

Our Second Facility

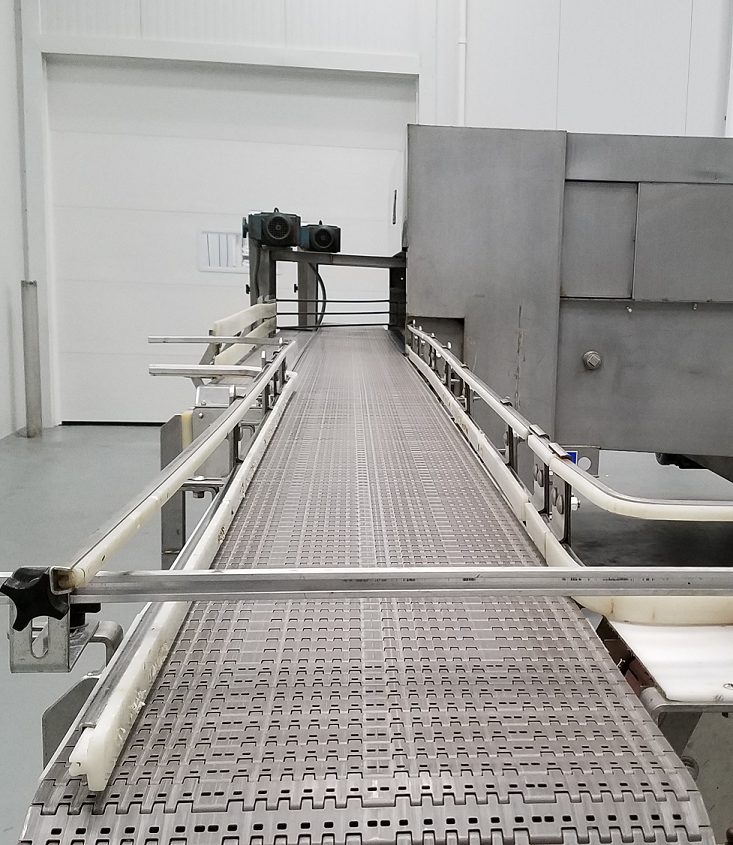

Maryland Packaging’s second facility – MP2 – was built in 2018 to accommodate larger HPP, bottling, and cold chain needs.

We can process 250,000,000 lbs of food through MP2.

It’s the perfect place for cold-chain vertical integration, including cold storage.

Our Second Facility

Maryland Packaging’s second facility – MP2 – was built in 2018 to accommodate larger HPP, bottling, and cold chain needs.

We can process 250,000,000 lbs of food through MP2.

It’s the perfect place for cold-chain vertical integration, including cold storage.

Core Competencies

@ MP2

MP2 is a cold facility with the ability to maintain 36 degrees in every room or fill at semi ambient temperature.

High Speed Bottling & Capping PET, PP and Glass many core bottles to choose

from

- Cold Fill (blended juices, baby foods, dips etc.…)

- Ambient fill (Date Syrups, Sweet Potato Syrup, Fig Syrup, Apricot Syrups, etc…)

- Hot Fill (Teas, Marinara Sauces, BBQ, Dipping Sauces etc…)

- Piston Filling

- Overflow Filling

- Major Cooling Tunnel

Labeling

- Pressure Sensitive

- Sleeves

VFFS

- Food Service

- Sauces

- Chutneys

- Dessert Sauces

- Syrups

Liquid PC cups

Spouted Pouches

- Hot fill (sauces, etc…)

- Cold Fill (Baby Foods, Juices, Lassies, etc.)

Tray Bundling

- All different sizes

HPP

- Hiperbaric 100,000,000 Lbs. capacity a year

Retort

Low production capacity at this time

Sous Vide

- Meats

- Seafood

- Vegetables

- RTE

Core Competencies

@ MP2

MP2 is a cold facility with the ability to maintain 36 degrees in every room or fill at semi ambient temperature.

High Speed Bottling & Capping PET, PP and Glass many core bottles to choose

from

- Cold Fill (blended juices, baby foods, dips etc.…)

- Ambient fill (Date Syrups, Sweet Potato Syrup, Fig Syrup, Apricot Syrups, etc…)

- Hot Fill (Teas, Marinara Sauces, BBQ, Dipping Sauces etc…)

- Piston Filling

- Overflow Filling

- Major Cooling Tunnel

Labeling

- Pressure Sensitive

- Sleeves

VFFS

- Food Service

- Sauces

- Chutneys

- Dessert Sauces

- Syrups

Liquid PC cups

Spouted Pouches

- Hot fill (sauces, etc…)

- Cold Fill (Baby Foods, Juices, Lassies, etc.)

Tray Bundling

- All different sizes

HPP

- Hiperbaric 100,000,000 Lbs. capacity a year

Retort

Low production capacity at this time

Sous Vide

- Meats

- Seafood

- Vegetables

- RTE