Baby Food Co-Manufacturing

Our first facility is perfect for small businesses looking to get started.

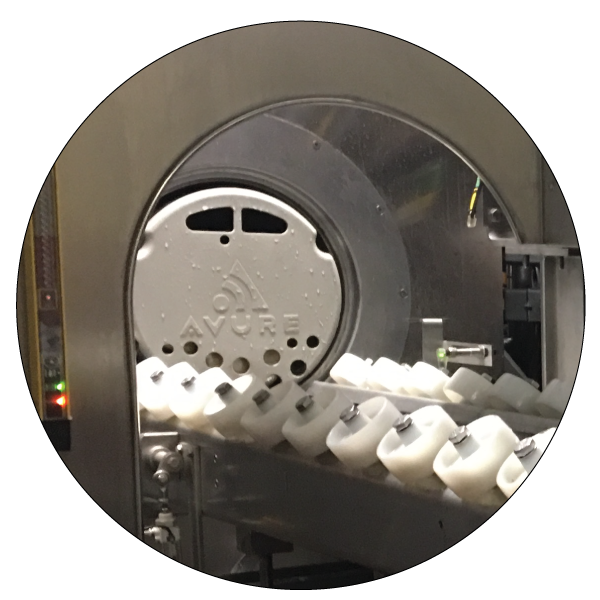

Our second facility caters to the needs of bigger operations with as much as 10 times the capacity of our first facility in some areas. For example, we’ll have two Hiperbaric 525 machines for natural HPP processing – the single highest capacity anywhere in the Mid-Atlantic.

Baby Food Co-Packaging

We have all the necessary equipment to get your product manufactured and packaged in your preferred style all under one roof.

Our facility is able to process 160 spouted pouches per minute.

High-Pressure Processing (HPP)

High Pressure Processing (HPP) can extend shelf-life by as much as 120 days WITHOUT the need for preservatives.

Have Questions?

We’re happy to answer any questions you have about getting your baby food product processed, manufactured, and/or packaged all under one roof at Maryland Packaging.

[gravityform id=”19″ title=”false” description=”false”]