What is High Pressure Processing (HPP)?

Whereas other types of food processing involve heat treatments which can destroy important nutrients and change the taste of your recipe, using HPP typically preserves your vitamin content, taste, and texture. All this without the use of harsh preservatives or chemicals.

How does it do this?

High Pressure Processing makes your food safe without the use of heat by applying extreme pressures to the product.

These pressures can reach 87,000 psi (pounds per square inch).

The pressure is applied equally from all directions, protecting the shape and structure of your food.

What happens at 87,000 psi? The cell membranes of pathogenic bacteria are crushed and rendered inert – completely harmless.

How High is the Pressure?

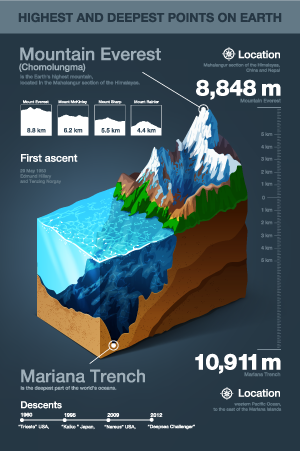

That’s the equivalent of being 27 miles under the ocean – a full 20 miles deeper than the Mariana Trench.

For Comparison…

This remote depression in the Earth’s crust is estimated to be roughly 35,814 ft below sea level – or just under 6.8 miles deep.

What happens at this depth? Some weird things.

For one, the pressure is described as the equivalent of “inverting the Eiffel Tower and resting the point on your bit toe.” Or, having a hundred full grown elephants standing on your head.

Deep sea diving equipment doesn’t use rivets because they could pop under pressure and be shot at the occupant with the same speed as a bullet.

The organic processes of animals living at this depth (known as the Hadal Zone, named after the God of the underworld), require special molecular innovations to thrive under such pressures. The reason: because several miles under water, even DNA can be distorted.

…and all of this happens at less than 7 miles of pressure.

To achieve the same pressures found in an HPP machine, you would need to dive an extra 20 miles beneath the Mariana Trench. Needless to say, no such oceanic depths exist on Earth.

One such reasonable comparison does exist, however – the Earth’s crust. At its thinnest (under the ocean),

the Earth’s crust is just 6 miles. At its thickest, the crust (which separates us from the hot, magma-filled mantle) can get up to roughly 31 miles thick. The depths imitated in a High Pressure Processing machine are closer to the Earth’s crust, than to its oceans.

A Brief History of High Pressure Processing (HPP)

In the late 1800s, scientists were experimenting with pressure processing to extend the shelf life of milk. At the time, they were able to get pressures up to roughly 12,000 pounds per square inch (compare this to the 87,000 psi achieved by today’s equipment). Unfortunately for dairy lovers of the late 1800s, this didn’t quite cut it.

In the early 1900s, scientists picked up the high pressure mantle again – this time experimenting with fruits, vegetables, and juices. Once again, they found that the pressures they were able to exert didn’t have the spore-killing effects they had hoped for.

It wasn’t until the 1990s that High Pressure Processing came to be used in commercial food preparation, starting in Japan, travelling to the U.K., and finally finding a home in U.S. markets.

Learn More About High Pressure Processing (HPP)

Want to HPP Your Product?

[gravityform id=”34″ title=”false” description=”false”]