HACCP – Hazard Analysis and Critical Control Points

It’s a systematic approach to preventing hazards from entering the food supply, first developed for use by NASA.

The food industry today has adopted this model, starting with Pillsbury in the early 1970s. While it’s not a legal requirement for all food types, many companies develop individual HACCP plans for each of the products that go through their facilities to maximize food safety.

What is HACCP?

The HACCP plan helps food producers create the safest products possible.

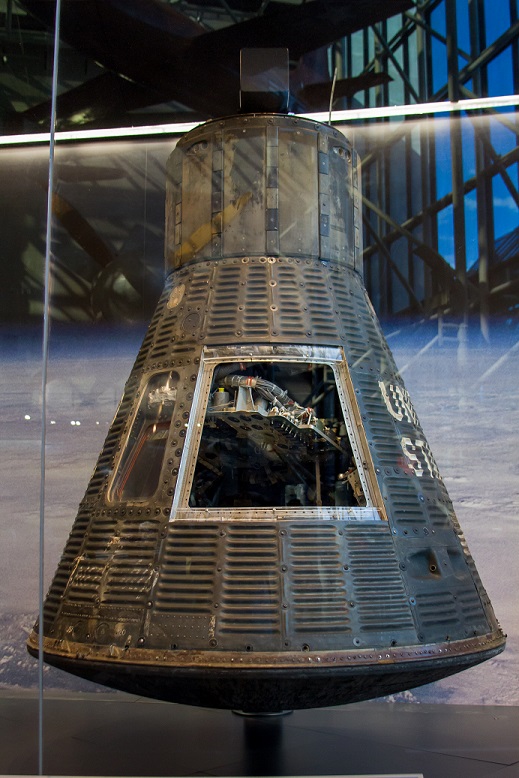

The system was first developed to solve food safety concerns for NASA astronauts.

When getting ready to send humans into space operating million-dollar equipment far from medical assistance or backup, ensuring the health of the astronauts became paramount.

It was quickly determined that traditional end-product testing wouldn’t be sufficient. NASA assembled a joint effort between the space program, the leading scientist at Pillsbury, and the United States Army Laboratories.

They used NASA’s existing Critical Control Point (CCP) requirements in engineering as a basis for their new food safety program.

With the success of the early HACCP system at NASA, Pillsbury began using the same system to prevent outbreaks in their own facility. In 1971, they were asked to present this system and training for it to the FDA.

The 7 Principles of HACCP

- Hazard analysis.

- CCP (Critical Control Point) identification.

- Establishing critical limits.

- Monitoring procedures.

- Corrective actions.

- Verification procedures.

- Record keeping and documentation.

Let’s look at each of these in order.

Principle 1: Hazard Analysis

Before you can begin to control for potential hazards, they must first be identified.

The first step in any HACCP plan is to analyze the food to be produced, how it’s made, how it will be distributed, what the intended end use is – and how all of these things will affect final product safety.

All ingredients and raw materials involved in the process are evaluated for potential hazards. Each hazard should also consider each step of the process, how it will be stored, how it will be distributed, and how it will be prepared on the consumer’s end.

There are three basic objectives involved in this process:

- Identify any potential hazards and their associated control measures.

- Identify any modifications that may be needed to improve or ensure the final safety of the product.

- Establish a basis that will be used to outline Critical Control Points (CCPs) in Principle 2.

A hazard analysis at one facility may look very different from one designed for a different facility – even when it’s concerning the same product. Each plan should be specific to the processes, equipment, and other elements used at the facility the product will be handled in.

The primary three categories of hazards analyzed are:

- Biological

- Chemical

- Physical

Principle 2: Determine Critical Control Points (CCPs)

A Critical Control Point (CCP) is a step in the food handling process during which controls need to be put into place to prevent, reduce, or eliminate the safety risk.

A successful HACCP plan will identify each CCP accurately and completely. A HACCP plan that has not accounted for every Critical Control Point is incomplete.

Some examples of Critical Control Points include:

- Heat treatment, or thermal processing

- Chilling

- Appropriate product formulation

- Testing for contaminants

Principle 3: Establish Critical Limits

For every Critical Control Point, there is a related Critical Limit.

These are maximum or minimum values that will be controlled at the CCP.

Limits must be based on the science of the product, ingredients, and other elements involved in the production of the food. These limits are established to prevent, reduce, or eliminate risk at each control point.

Some critical limits may apply to:

- Temperatures

- pH, or acidity

- Water activity

Principle 4: Establish Monitoring Procedures

Some monitoring will be continuous, while other measures may be scheduled at appropriate intervals to ensure product safety.

This monitoring is to ensure that each Critical Control Point is being within the Critical Limit needed to keep the food safe. If it’s found that a deviation has occurred, or there’s a trend towards deviation, measures need to be taken to ensure that it’s brought back under control, and that corrective actions are taken immediately for any product involved in the deviated process.

Monitoring also provides an accurate and detailed record of the Critical Control Points. These records should include what was monitored, the initials of the individual doing the monitoring, and the date.

The accuracy and efficacy of this monitoring process is crucial to the overall HACCP system and the safety of the final end product.

The plan, itself, should describe the monitoring to take place, as well as what role within each organization is assigned to each step of monitoring.

Principle 5: Establish Corrective Actions

The purpose of a HACCP plan is to prevent Critical Control Points from straying outside the parameters presented by the Critical Limits, but the plan should also account for what’s to be done if a deviation does occur.

One of the primary functions of corrective action is to keep foods that may have hazards introduced from reaching consumers. If there deviations beyond Critical Limit, actions need to be taken to prevent that hazard from causing harm.

At this point, the cause of non-compliance also needs to be investigated to maximize food safety moving forward.

Each of these corrective actions needs to be timely, as well as properly recorded. All documentation on this matter should be kept in records.

Principle 6: Establish Verification Procedures

The verification process starts before the HACCP plan is enacted and continuously to ensure that it is implemented effectively.

The purpose here is to ensure that the processes outlined, the Critical Control Points, and the Critical Limits are all scientifically valid and will ensure food safety.

Often, this means having the plan evaluated by an expert in the field, by scientific studies, and by in-house observations and tests. These should work together to verify the scientific justification for each step – or, amend the HACCP plan as needed.

Principle 7: Record-Keeping and Documentation Procedures

Detailed, accurate documentation is crucial at every step of the HACCP plan, as well as food production.

This includes records established in the monitoring phase of the HACCP system and documentation of the reasoning behind the HACCP plan as it is laid out.

The FDA provides a helpful table that can be used as a guideline when organizing the layout of your own HACCP plan here.

Maryland Packaging Goes Above and Beyond

Our founders have been in the food business for over 30 years. We know the ins and outs of all the state and federal requirements for what we do.

We’ve also been witness to numerous public health scares that have hit other companies in our industry.

We’re not satisfied with doing only what we must. We do everything in our power to protect the foods we come into contact with.

To that end, we regard HACCP as our ally.

When we create a HACCP plan, it’s strict application is an investment. It’s an investment in ourselves, in our clients, and in the consumer.

Every one of our employees who comes into contact with your product is required to undergo HACCP certification. Adherence to these plans is mandatory. Evaluation of each plan is conducted by our most experienced food industry experts.

Implementation and follow-through is supervised and documented from start to finish.

When it comes to food safety, we leave nothing to chance.